Brush Motors vs Side Channel Blowers in Dustless Sandblasters: Reliability, Maintenance, and Real-World Experience

Selecting the right extraction system for a dustless sandblaster is a fundamental decision that affects not only comfort and productivity, but also long-term operating costs and machine reliability. The Sandblast Tech range features two main types of extraction systems: traditional brush (commutator) motors and advanced side channel blowers. This article, based on years of experience at Sandblast Tech and in-depth analysis of both technologies, is designed to help you make an informed choice that will bring tangible benefits to your stonework business.

Brush Motors in Dustless Sandblasters – An Apparently Cheap Option with Hidden Pitfalls

Brush motors have long been used in various industrial vacuum cleaners due to their simple construction and relatively low initial cost. In Sandblast Tech sandblasters, they are found in:

◆ SB Zephyr: fitted with a single 1.2 kW brush motor, dedicated mainly to mobile work such as cemetery inscriptions.

◆ SB Plus: equipped with two brush motors, offered as a budget solution for smaller workshops.

How they work and their theoretical advantages:

Brush motors use carbon brushes to transfer current to the armature commutator, generating suction. Their main advantage is a lower purchase price for the entire sandblaster.

The harsh reality of sandblasting and motor lifespan:

Under ideal conditions, brush motors can last from 1,000 to 3,000 hours. However, the operating environment of a dustless sandblaster-even with filtration systems-is extremely harsh. Sandblast Tech’s experience and customer feedback show that actual brush motor life in intensively used sandblasters is just 1–2 years. In the past, even larger models such as the SB Eol Plus and SB Orkan (single-phase versions with brush motors) suffered from rapid motor wear, with failures occurring after as little as one year under heavy load. This was the main reason for switching to much more durable side channel blowers in these models.

Key problems and hidden costs of brush motors in sandblasters:

◆ Ubiquitous dust: Despite filters, a certain amount of fine abrasive dust always enters the motor, settling on the brushes, commutator, and sleeve bearings, acting like sandpaper and drastically accelerating wear.

◆ Neglected maintenance: Many users do not follow manufacturer recommendations for regular filter cleaning or replacement. A clogged filter significantly increases motor load, leading to overheating and premature failure.

◆ Frequent brush replacement: Carbon brushes are consumables and must be replaced every 400–600 hours. A set of brushes costs around €50–100, and replacement is usually carried out by the user, as service centres rarely offer this as a standalone service.

◆ High failure and replacement costs: If more serious damage occurs (e.g., worn commutator, seized bearings), repairing a brush motor is often uneconomical. Standard practice is to replace the entire motor, costing around €100 per motor (SB Zephyr has one, SB Plus has two), plus labour of €300–400 per replacement. This means that every 1–2 years, users may face a significant expense.

◆ Downtime: Every failure or brush change means machine downtime and delays in job completion.

◆ Decreased efficiency and increased noise: As brushes wear and filters clog, suction efficiency drops. Brush motors are also noisier and less energy-efficient than side channel blowers.

When is a brush motor sandblaster still a viable option?

◆ SB Zephyr: A mobile model for occasional use, mainly for cemetery inscriptions, where daily jobs are limited (e.g., up to 10 inscriptions per day). Less frequent and less intensive use translates to longer motor life in this application.

◆ SB Plus: A budget option for small workshops with modest throughput, where the owner is aware of the need for regular maintenance and accepts higher long-term costs and risk of failures in exchange for a lower entry price.

Side Channel Blowers – Investing in Reliability, Performance, and Long-Term Savings

Side channel blowers (also known as regenerative blowers or ring blowers) are a completely different class of extraction device, engineered for continuous operation in demanding industrial settings. In the Sandblast Tech range, they power:

◆ SB Eol Plus: with a 1.5 kW side channel blower (single-phase version available), ideal for small to medium-sized workshops.

◆ SB Orkan Plus: with a 2.2 kW side channel blower (available in single- and three-phase versions), designed for intensive use in large workshops.

Technology and key advantages:

Side channel blowers operate on the principle of contactless air compression-the impeller rotates at high speed without touching the housing. The absence of wearing parts (such as brushes) and the separation of the working chamber from the drive motor make them extremely durable and resistant to harsh conditions.

◆ Impressive lifespan: Side channel blowers are designed for 20,000 to even 40,000 hours of trouble-free operation. In practice, this means 8–12 years or more of intensive use without the need for major overhauls.

◆ Minimal maintenance: No brushes to replace. Maintenance is limited to periodic inspection and cleaning of the sandblaster’s filters.

◆ Consistent, high suction performance: Blowers maintain strong suction throughout their service life, which is crucial for effective abrasive recovery and dustless operation.

◆ Dust resistance: The design makes them practically immune to dust that would otherwise destroy brush motors.

◆ Lower noise and higher energy efficiency: They run quieter and use less energy than brush motor-based systems of comparable suction power.

◆ Ideal for continuous and automated use: Reliability and durability make them perfect for multi-hour shifts and integration with automation, such as the CNC Akwilon table.

◆ Dry air required: Due to the closed abrasive loop and precise separation system, sandblasters with side channel blowers require dry compressed air (a compressor with an air dryer is necessary), as moisture can disrupt the separation process.

Higher initial cost, lower long-term expense:

Sandblasters with side channel blowers have a higher purchase price. However, considering the drastically lower maintenance costs, absence of downtime due to motor failures, and much longer service life, the investment pays off many times over within a few years.

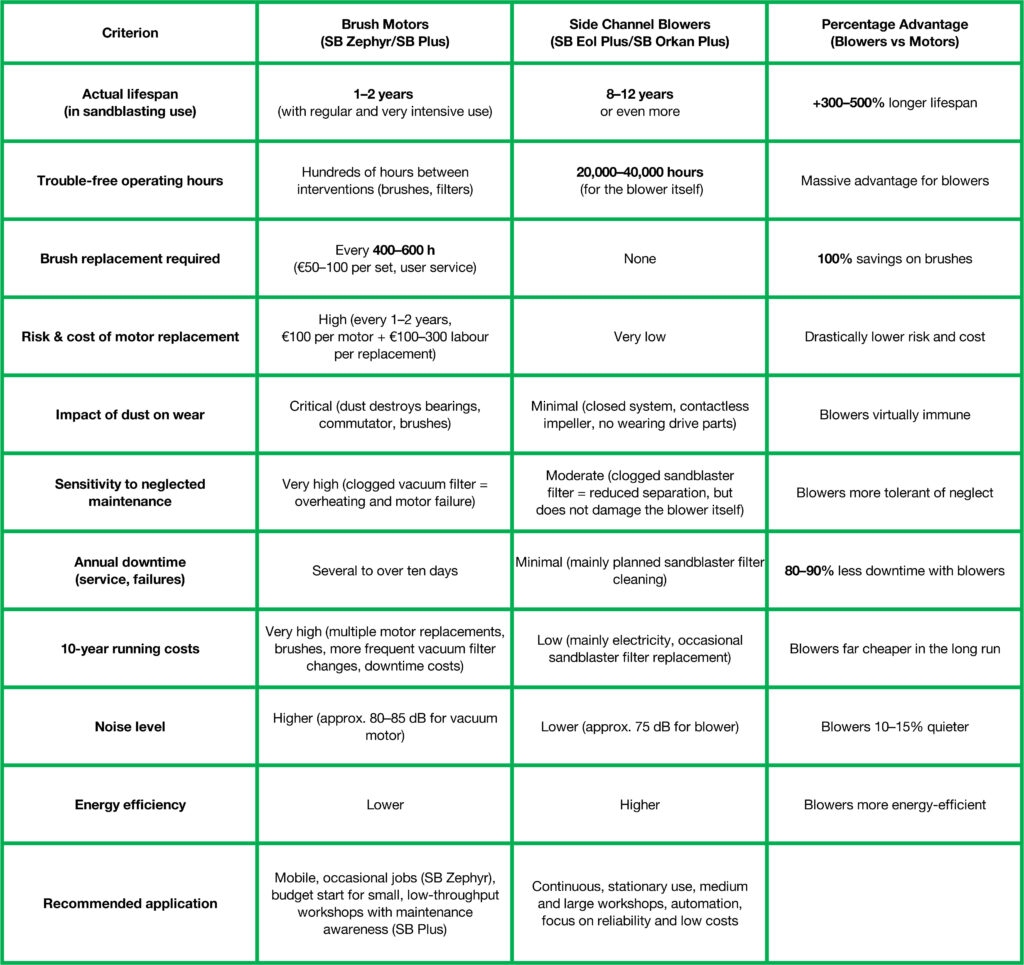

Direct Comparison: Brush Motors vs Side Channel Blowers

Additional Real-World Insights

◆ Brush motor maintenance is typically user-performed: Most users replace brushes themselves, as service centres rarely offer this as a standalone service. When the motor fails, the whole unit is usually replaced, significantly increasing costs.

◆ Dust always finds its way in: Even with good filtration, some dust passes through the turbine, sleeve bearings, and brushes, accelerating wear-especially when users neglect regular filter cleaning or ignore manufacturer recommendations. This is a major factor in the short lifespan of these motors.

◆ Overloading from clogged filters: Failure to clean dust filters leads to blockages, increased load, overheating, and rapid motor failure.

◆ Typical lifespan in sandblasters: In real-world use, brush motors last only 1–2 years-even less under heavy load. This is based on years of Sandblast Tech’s experience; previous single-phase SB Eol Plus and SB Orkan models with brush motors often required motor replacement after just one year.

◆ None of these issues affect side channel blowers: Their design is inherently resistant to dust, moisture, and user neglect, making them virtually maintenance-free.

◆ Brush motors are now only used in the mobile SB Zephyr: This model is designed for occasional cemetery work, where the machine is used only when enough jobs have accumulated (up to 10 inscriptions per day), so infrequent use extends motor life.

◆ SB Plus is intended for small businesses with low throughput: It is a budget solution, so higher running costs and maintenance are a trade-off for the lower purchase price.

◆ Brush motor cost: A single motor costs around €100 (SB Zephyr has one, SB Plus has two). Labour for replacement is €300–400, making each failure a significant expense.

Summary and Recommendations

◆ For professional workshops: Side channel blowers (SB Eol Plus/SB Orkan Plus) are the clear choice. Their higher initial cost is quickly offset by reliability, minimal maintenance, and long service life.

◆ For mobile, occasional work (cemeteries): SB Zephyr with a brush motor is suitable, provided the user is disciplined with maintenance and accepts higher long-term costs.

◆ For small businesses: SB Plus is a compromise for those with low throughput and a limited budget, but with the understanding that maintenance and failures will be more frequent.

Service statistics: 80% of brush motor failures are due to neglected filter cleaning. Side channel blower failures are rare and usually result from mechanical damage (e.g., machine being dropped).

Investing in technology that minimises user error is the future of professional sandblasting-side channel blowers are the industry standard for reliability and cost-effectiveness.