- Home

- Machines

- Compressors

- Accessories

- Knowledge base

- News

- Contact Us

Rotary screw compressors GudePol SMART Series with no air dryer

IN Compressors, Rotary screw compressors

Description

Smart Series Screw Compressors are a new line of compressors designed for use in workshops and small businesses. The compressor of the SMART series is a compact device with an aesthetically shaped housing with a tank occupying up to 1.7 m3 of space. Its optimal performance when using a 5.5 kW or 15 kW motor is from 650 l / min to as much as 1800 l / min at a pressure of 8 to 13 bar. It is characterized by high reliability and high technical level. Low maintenance costs of the device, full integration of devices such as a refrigerant dryer and compressed air filters, continuous operation with an optimal noise level of up to 68 decibels, the use of a microprocessor control system for the compressor and ease of use make the SMART compressor series have an excellent price-to-performance ratio and quality.

Upgrades for HIT and SMART series

Upgrade – galvanized tank – 100%

Standard blue painted tank in screw compressors HIT and SMART Series, can be replaced by galvanized tank inside and outside in ISO standard DIN EN ISO-1461. This option gives maximum rotection against corrosion, extending long life of compressor.

Galvanized tanks have a 10-year warranty.

Upgrade – AFD adjustable-frequency drive

Generally speaking, a frequency converter is an electronic device whose task is to convert AC energy with a constant voltage amplitude and constant frequency into energy with variable frequency and variable voltage amplitude adjustable to the needs.

A frequency converter is a device used for smooth regulation of the rotational speed of electric motors while maintaining the best possible operational parameters.

The use of a frequency converter in our screw compressors allowed to obtain very good control properties of induction motors, ensuring, with proper control, obtaining the full torque of the motor at low rotational speeds while maintaining a constant pressure in the compressed air network with its variable outflow.

Each screw compressor with a frequency converter has the possibility of speed control in the range from 50% to 100%, and thus also in this capacity range. The continuously variable speed control of the compressor is the most economical way of regulating.

The main advantages are lower electricity consumption compared to traditionally controlled compressors and maintaining a constant set pressure in the compressed air network.

Compressor equipment and TECHNICAL SPECIFICATIONS

All our screw compressors have a 2 years warranty.

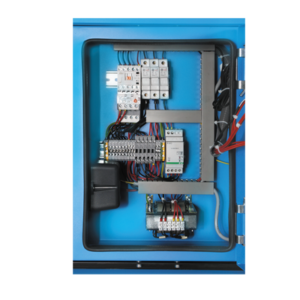

Compressor SMART is equipped with a microprocessor panel control system L26S which informs you of the current operation of the compressor.

L26S visualizes (selection of 8 languages: Italian, English, French, German, Spanish, Portuguese, Turkish, Polish) on the back light alphanumerical LCD the status of the compressor in real time, detects and shows the failures shutting the compressor off automatically. Thanks to the internal clock L26S allows to set up to three working cycles per day in one week. L26S is equipped with serial port RS485 for the connection to Gudepol Internet Cloud. L26s allows connect GSM unit to sending messages on status or failures of the compressor. Control panel allows connect second compressor equipped with L16-S, L18, L26S for Master/Slave operation.

A clear and detailed display provides information about:

– alarm code

– temperature of airend

– total hours overall and load

– time for the review of the service.

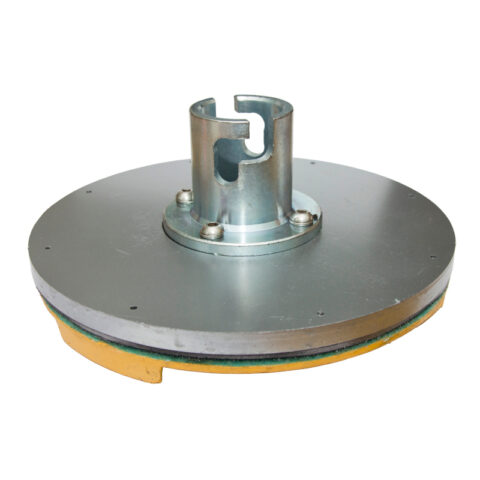

The air-end is made of a screw-top compressor pumping system components SMART series has one of the best on the market effective performance indicators proposal to engine power.

Filters and oil separator was integrated with airend to reduce number of connections with the rest of components to a minimum. That help to achieved the highest level of reliability.

Extremely efficient, dual-function cooler for optimum working in the hardest conditions.

This allows to achieve low temperature air to the pneumatic line.

Cooler is conected with airend by high-temperature hydraulic hoses.

Modern automatic based of the highest quality components, protects the compressor against:

voltage drop in the power line

– power failure

– wrong direction of motor rotation

– motor and cooler fan overload

– too high oil temperature

– too low oil temperature

– start up undischarged airend

Automatic electromagnetically-controlled valve basis on continuous measurements of the condensate level in the tank opens depending on the needs and creates a continuous drain of compressed air from the system without loss of pressure.

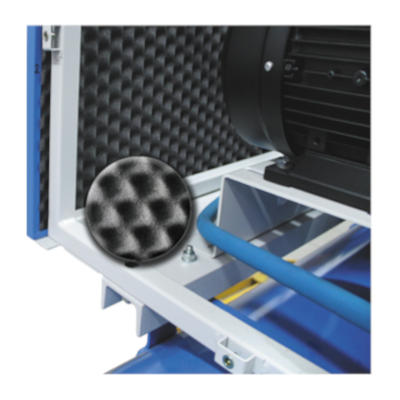

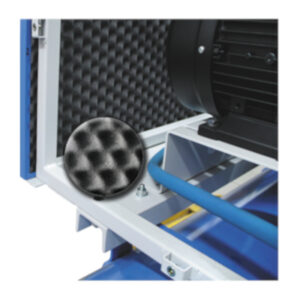

The housing of the SMART screw compressor has a compact housing that has been made with high precision.

The soundproofing plates installed inside the casing together with the compressor’s constructional arrangement made it possible to achieve the noise barrier of 68 [dBA], which is one of the best results in this class of compressors.

Technical parameters of SMART VT screw compressors with tank and no air dryer

…