- Home

- Machines

- Compressors

- Accessories

- Knowledge base

- News

- Contact Us

Rotary screw compressors GudePol VSA Series 18.5-22 kW

IN Compressors, Rotary screw compressors, Rotary screw compressors GudePol VSA Series 18.5-22 kW

Description

The GUDEPOL VSA series screw compressor has been constructed based on the most modern world solutions associated with the highest quality materials. The VSA series is a perfect source of compressed air in a modern pneumatic line. It enables the selection of appropriate components, such as: pressure tank, dryer, central filters. The sound-absorbing, compact housing allows versatile positioning of the compressor due to low noise emissions.

Compressors VSA common features:

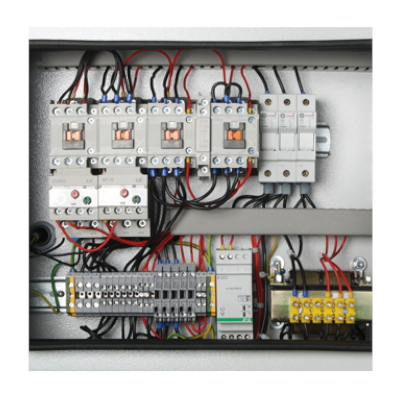

- Compressor advanced panel is equipped with a microprocessor control system. This solution allows for easy and clear operation.

- The system automatically detects irregularities and inform, displaying the type of fault. In case of damage threat it?s shutting down whole device. Control panel inform about the current operation of the compressor.

- A clear and detailed display provides information about: alarm code, temperature of airend, total hours overall and load, time for the review of the service.

- Standard Electronic pressure transducer facilitates precise selection work pressure through the control panel.

- IP55 insolation of Electrical engine, star delta start.

- Compact design, allow transport through the narrow door.

- Adjustable legs for easy level setting.

- Direction of rotation or phase failure.

- Built-in emergency stop button.

- Internal used sound absorbing materials.

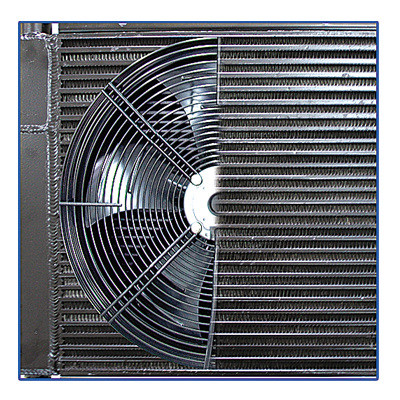

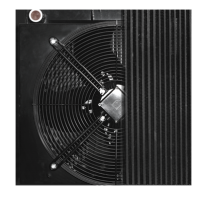

- Extremely efficient, dual-function cooler.

- Belt drive with taper-lock system – accurate and easy to set the transmission system.

- Housing covers easy to remove (locks) – easier service access.

Upgrades for HIT and SMART series

Upgrade – AFD adjustable-frequency drive

Generally speaking, a frequency converter is an electronic device whose task is to convert AC energy with a constant voltage amplitude and constant frequency into energy with variable frequency and variable voltage amplitude adjustable to the needs.

A frequency converter is a device used for smooth regulation of the rotational speed of electric motors while maintaining the best possible operational parameters.

The use of a frequency converter in our screw compressors allowed to obtain very good control properties of induction motors, ensuring, with proper control, obtaining the full torque of the motor at low rotational speeds while maintaining a constant pressure in the compressed air network with its variable outflow.

Each screw compressor with a frequency converter has the possibility of speed control in the range from 50% to 100%, and thus also in this capacity range. The continuously variable speed control of the compressor is the most economical way of regulating.

The main advantages are lower electricity consumption compared to traditionally controlled compressors and maintaining a constant set pressure in the compressed air network.

|

|

Control panel L33S

The L33S control panel upgrade includes a production replacement of the standard L26S control panel in VS compressors with the L33S model. The L33S control panel upgrade includes all the features of the standard L26S solution plus the following advantages:

– MULTIUNIT function means supervisory control with the possibility of managing 4 slave compressors in 3 operating modes

– intelligent – maximum efficiency with minimum energy consumption

– equivalent (hourly) – setting the operation of compressors of the same power, in which the devices are consumed alternately and evenly according to the schedule of hours

– priority – setting work priorities for individual compressors

– the ability to control and monitor the operation of the inverter

– RS485 port allows the compressor to be connected to Gudepol Internet cloud in order to monitor the operation of the device.

Heat exchanger

The new WH heat exchanger model is a great way to increase savings. The heat efficiency of the exchanger can be used for the heating system as well as for heating domestic water. With the WH exchanger system, we have 75% of the electric power consumed by the compressor from the network at our disposal.

Thanks to the durable and optimized structure, the WH exchanger is adapted to effective operation for many years in the entire range of applications.

The innovative pattern of ribbing on the WH exchanger plates makes it the best heat exchanger on the market, significantly reducing energy consumption and reducing CO2 emissions.

Front plate materials: AISI 304L; Plates: AISI 316L;

Connection nozzles: AISI 304L; Solder material (binder): copper

Compressor equipment and TECHNICAL SPECIFICATIONS

All our screw compressors have a 2 years warranty.

Compressor SMART is equipped with a microprocessor panel control system L26S which informs you of the current operation of the compressor.

L26S visualizes (selection of 8 languages: Italian, English, French, German, Spanish, Portuguese, Turkish, Polish) on the back light alphanumerical LCD the status of the compressor in real time, detects and shows the failures shutting the compressor off automatically. Thanks to the internal clock L26S allows to set up to three working cycles per day in one week. L26S is equipped with serial port RS485 for the connection to Gudepol Internet Cloud. L26s allows connect GSM unit to sending messages on status or failures of the compressor. Control panel allows connect second compressor equipped with L16-S, L18, L26S for Master/Slave operation.

A clear and detailed display provides information about:

– alarm code

– temperature of airend

– total hours overall and load

– time for the review of the service.

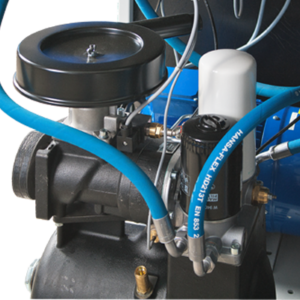

The air-end is made of a screw-top compressor pumping system components SMART series has one of the best on the market effective performance indicators proposal to engine power.

Filters and oil separator was integrated with airend to reduce number of connections with the rest of components to a minimum. That help to achieved the highest level of reliability.

Reliable drive train, ensuring the stable operation of the compressor. Throughout the service interval, the compressor maintains its performance at the highest level. The electric motor meets all the quality standards in Europe, its undeniable features are:

– excellent reliability

– quiet operation, no vibrations

– environmentally friendly production technology

Extremely efficient, dual-function cooler for optimum working in the hardest conditions.

This allows to achieve low temperature air to the pneumatic line.

Cooler is conected with airend by high-temperature hydraulic hoses.

Modern automation based on the highest quality components protects the compressor against:

– a drop in voltage in the electrical network

– failure of the supply phase

– wrong direction of engine rotation

– overload of the electric motor or the radiator fan

– too high oil temperature

– too low oil temperature

– starting an unbalanced screw module

The installation of an electronic pressure transducer facilitates the precise selection of working pressures via the control panel.

The housing of the SMART screw compressor has a compact housing that has been made with high precision.

The soundproofing plates installed inside the casing together with the compressor’s constructional arrangement made it possible to achieve the noise barrier of 68 [dBA], which is one of the best results in this class of compressors.

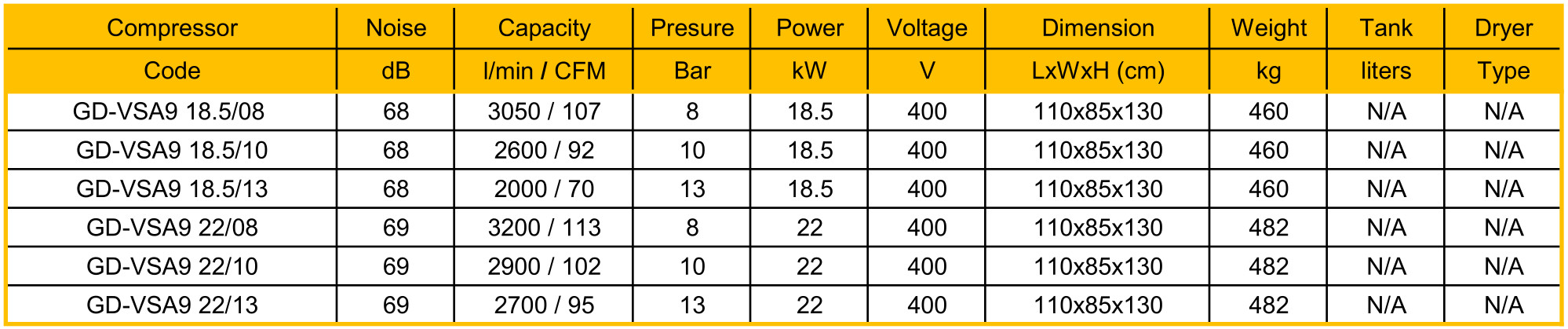

Technical parameters of SMART screw compressors with no tank and no air dryer

.

.