- Home

- Machines

- Compressors

- Accessories

- Knowledge base

- News

- Contact Us

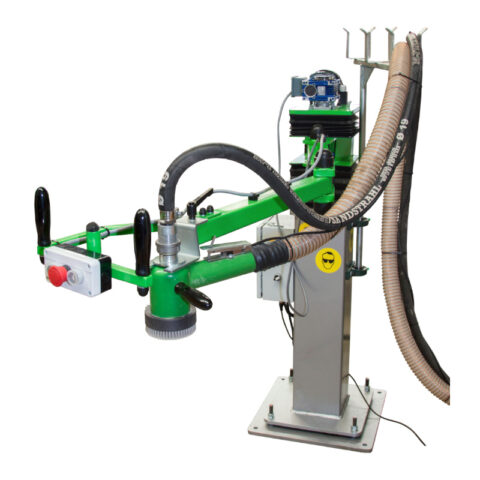

Dustless sandblaster SB Orkan Plus

IN Dustless sandblaster SB Orkan Plus, Dustless sandblasters, Machines

Advanced, Efficient, and Safe Sandblasting for Professional Stonework

In the world of modern stone processing, efficiency, operator safety, and cost-effectiveness are no longer optional-they are essential. The SB Orkan Plus stands out as one of the largest, most powerful, and technologically advanced dustless sandblasters available on the market today. It has been engineered for professionals who demand robust performance, long-term reliability, and a healthy working environment. By investing in the SB Orkan Plus, you are choosing a solution that will elevate your workshop, protect your team, and drive the growth of your business.

Key Features & Applications

The SB Orkan Plus is designed for intensive, daily use in stone fabrication workshops and wherever speed, consistency, and premium surface quality are required. Its large abrasive tank and advanced technical solutions make it ideal for sandblasting headstones as well as larger architectural elements and decorative stonework.

Flexible Power Options & Robust Extraction

To suit a variety of workshop setups, the machine is available with a 2.2 kW abrasive extraction suction pump in both three-phase and single-phase versions, allowing you to match the power supply to your facility’s infrastructure and your operational needs. This ensures reliable, maintenance-free operation for many years.

Advanced Triple-Stage Abrasive Recovery & Dust Separation

The SB Orkan Plus features a triple-stage, closed-loop system for dust separation and abrasive recovery. This allows for multiple reuses of high-quality media (abrasive), significantly reducing operating costs and minimising waste. Dust is efficiently separated and expelled from the system, while the abrasive is recirculated until it is fully spent.

Note: Due to the closed abrasive circulation, an air compressor with an air dryer is required to supply the machine with dry compressed air. Moisture in the system can negatively affect the separation process.

Sandblasting Nozzle Options

Depending on your production requirements, the SB Orkan Plus can be fitted with either a 5 mm or 6 mm sandblasting nozzle. This flexibility allows you to tailor the machine’s performance to the type of stone being processed and the desired throughput.

Intuitive Operation & Abrasive Level Monitoring

A modern, round sight glass installed in the pressure vessel allows for quick and easy visual inspection of the abrasive level-just a glance is enough to determine if a refill is needed. Additionally, a minimum abrasive level sensor alerts the operator when it’s time to add more material, ensuring uninterrupted workflow.

Dual Filter Cleaning System

Maintaining a clean air filter is critical for trouble-free operation. The SB Orkan Plus is equipped with two independent filter cleaning systems:

– Pneumatic system – delivers a sudden, powerful blast of compressed air to shake the filter and dislodge dust,

– Mechanical hammer system – vibrates the filter to remove any remaining dust particles.

These systems keep the filter in optimal condition, maximise abrasive extraction efficiency, and minimise manual maintenance.

Operator Safety & Comfort

Operating the SB Orkan Plus is completely dust-free, dramatically improving workshop conditions and protecting the health of all staff-especially those with respiratory sensitivities. There is no need for sandblasting helmets or specialised protective suits; any team member can operate the machine safely and comfortably.

Cost Savings & Efficiency

The triple-stage abrasive recovery system significantly reduces material costs and eliminates the need for time-consuming post-blasting cleanup. Over the long term, this translates into substantial financial savings and increased productivity throughout your operation.

Optional: Autan Support Arm and Compatibility with the CNC Akwilon Automatic Sandblasting Table

On request, the SB Orkan Plus can be equipped with the professional Autan support arm, specially designed for use with dustless sandblasters. This innovative accessory relieves the operator from having to constantly hold the sandblasting head, enabling longer, more precise, and consistent work-even during deep engraving or on large surfaces.

The Autan Support Arm allows for even one-handed operation, simplifies training for new staff, and enables quick detachment of the blasting head for fully manual work when required. The integrated geared motor provides convenient height adjustment of the brush head, further enhancing comfort and precision.

We strongly recommend purchasing the SB Orkan Plus together with the Autan Support Arm-this combination not only boosts productivity and ergonomics but also ensures outstanding results during extended sandblasting sessions, reduces operator fatigue, and guarantees repeatable, high-quality inscriptions and decorative finishes.

Support Arm Autan – https://sandblast-tech.com/product/sandblasting-support-arm-autan-for-dustless-blasters/

Additionally, SB Orkan Plus is fully compatible with the CNC Akwilon Automatic Sandblasting Table. This combination enables automation of the sandblasting process, ensuring repeatability, high quality, and significant time and labour savings for the operator. The synergy between these devices allows you to fully exploit the potential of modern technology in everyday stonework production.

CNC Akwilon Automatic Sandblasting System – https://sandblast-tech.com/product/cnc-automatic-sandblasting-table-akwilon/

The SB Orkan Plus is an investment in cutting-edge technology, safety, and the future of your business. If you are looking for a machine that can meet the most demanding challenges and give you a competitive edge, this is the solution you’ve been searching for.

TECHNICAL SPECIFICATIONS

– 400V / 50Hz power supply

– 2.2 kW power

– Working pressure 2-4.5 Bar

– Air consumption – 35 cfm (1000 l / min)

– Abrasive dose adjustment – through the abrasive metering valve

– Nozzle – 5-6 mm

– Feeding tank – 60 liters (about 100 kg of abrasive)

– Pressure vessel – 60 liters

– Air filter cleaning – pneumatic and mechanical hammer

– Dust/Abrasive separation system – triple separation

– Abrasive level sensors -lower level

– Abrasive maximum level control – Round sight glass in the tank

– Recommended abrasive – alumina oxide

– Machine weight -200 kg

– Machine dimensions (HxWxD) 1880x860x1050 mm

Complete Your Setup

Expand Your Workshop with Matching Equipment