- Home

- Machines

- Compressors

- Accessories

- Knowledge base

- News

- Contact Us

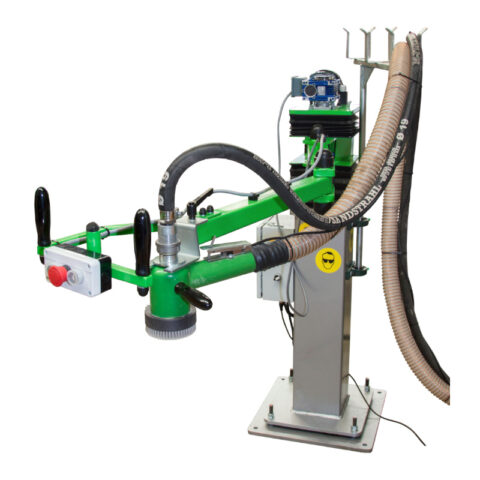

CNC AKWILON Automatic Sandblasting System

IN Automatic sandblasting system, CNC AKWILON Automatic Sandblasting System, Dustless sandblasters, Machines

CNC Akwilon Automatic Sandblasting System – Precision, Efficiency, and Growth for Your Business

In today’s competitive stonework industry, where quality, speed, and repeatability are paramount, the CNC Akwilon Automatic Sandblasting System redefines what is possible. Designed for workshops committed to innovation and growth, this advanced solution streamlines production, maximises efficiency, and dramatically reduces operational costs—making it the ideal choice for companies of all sizes, from expanding small businesses to large-scale manufacturers.

While its core application is the precise processing of memorial stone, the CNC Akwilon’s versatility extends to a wide range of flat materials, including glass and steel. This flexibility opens new opportunities and strengthens your market position.

Intelligent Automation – Your New Team Member

The CNC Akwilon system is more than just a machine—it is an intelligent, autonomous unit that takes over the most demanding and repetitive stages of sandblasting, delivering unmatched precision and consistency.

▸ Full Process Control – The operator has complete, individual control over every aspect of sandblasting for each project element.

▸ Number of passes: Adjust intensity for each section.

▸ Head speed: Set optimal working speed for the material and desired result.

▸ Step (lateral movement): Match to the nozzle diameter for perfect coverage.

▸ Pressure: Control abrasive impact for precise depth and quality.

▸ Abrasive selection: Use high-quality abrasives for best results.

▸ Real-Time Adjustments – All parameters can be modified before or during the process, and even repeated for selected elements, ensuring maximum flexibility and precision.

Advanced Integration with Dustless Sandblasters

The CNC Akwilon is engineered to work seamlessly with Sandblast Tech’s top dustless sandblasters—SB Orkan Plus or SB Eol Plus.

SB Orkan Plus – https://sandblast-tech.com/product/dustless-sandblaster-sb-orkan-plus/

SB Eol Plus – https://sandblast-tech.com/product/dustless-sandblaster-sb-eol-plus/

The system intelligently manages the process:

▸ Automatic Abrasive Level Detection: The machine pauses sandblasting when the abrasive is low, allowing for safe refill.

▸ Resume from Last Position: After refilling, work continues exactly where it left off, preventing errors.

▸ Abrasive Refill Notifications: The system alerts the operator when more abrasive is needed.

▸ Automatic Filter Cleaning: The CNC Akwilon initiates filter cleaning cycles, maintaining peak performance.

▸ Automatic Surface Vacuuming: After sandblasting, the head vacuums the surface, leaving it clean and ready for the next step.

▸ Reliability After Power Failure: Thanks to its memory function, the system resumes from the last saved position after unexpected interruptions.

User-Friendly Operation and Comfort

Despite its advanced technology, the CNC Akwilon is intuitive and easy to use:

▸ Modern PLC Controller with Touchscreen: Simple programming, parameter adjustment, and real-time monitoring.

▸ Manual Controller on a Long Cable: For precise, hands-on adjustments and corrections.

▸ Dedicated Software: Includes specialised software for sandblasting, such as rectangular frames on mirrors or glass.

Flexibility and Customisation

▸ Optimal Working Area (1200×1200 mm): Standard size for most tasks, with options to expand as needed.

▸ Compatibility: Designed for Sandblast Tech dustless sandblasters, but can be adapted to other brands if required.

An Investment That Pays for Itself

▸ Time Savings: The machine works continuously and efficiently, completing tasks much faster than manual methods.

▸ Lower Labour Costs: Operators can supervise multiple machines or focus on other tasks, boosting overall productivity.

▸ Reduced Errors and Waste: CNC precision ensures accuracy, minimising costly mistakes and material waste.

Unmatched Quality and Repeatability

▸ Perfectly Uniform Results: Every detail, line, and depth is executed with consistent precision.

▸ High-Quality Inscriptions and Decorative Work: Even the most complex designs are reproduced flawlessly.

▸ Increased Customer Satisfaction: Superior finished products enhance your company’s reputation.

Workplace Safety and Health

▸ Dust-Free Environment: Operators are protected from abrasive and dust exposure.

▸ No Heavy Protective Gear Required: Work comfortably without cumbersome helmets or suits.

▸ Reduced Physical Fatigue: The machine handles the hardest work, allowing operators to focus on quality.

Eco-Friendly Production

▸ Minimised Dust Emissions: Advanced dust extraction and filtration systems protect the environment.

▸ Efficient Abrasive Use: Closed-loop systems reduce waste and lower costs.

Summary

The CNC Akwilon Automatic Sandblasting System is more than just a machine—it is a comprehensive solution that will transform your business. With its intelligent automation, user-friendly controls, and integration with leading dustless sandblasters, it delivers tangible benefits in efficiency, quality, and safety. Choose CNC Akwilon and join the industry leaders who are shaping the future of stonework.

Contact us today to discover how CNC Akwilon can revolutionise your workshop.

TECHNICAL SPECIFICATIONS

– 220-240V / 50Hz power supply (or adapted to all countries)

– Total power – 0.3 kW

– Control – PLC touch screen + Manual Controller

– Head height adjustment range – 0-150 mm

– Working area – standard 1200 x 1200 mm (variable at the customer’s request)

– Recommended sandblaster model – Dustless Sandblaster

– Machine weight – 500 kg

– Machine dimensions (HxWxD) – 1760 (with higher legs 2060)x2050x1940

Complete Your Setup

Expand Your Workshop with Matching Equipment