- Home

- Machines

- Compressors

- Accessories

- Knowledge base

- News

- Contact Us

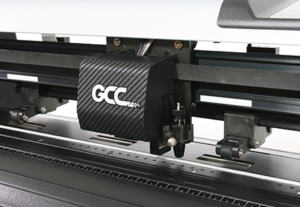

Vinyl cuttinig plotter Jaguar V

IN Accessories, Vinyl cutting plotters

Description

The Jaguar V plotter has been designed to meet the expectations of even the most demanding users. The JAGUAR V series is intended for everyone who professionally deals with graphics cut from self-adhesive foils and other materials.

A very stable construction of the plotter based on an internal steel frame. Each plotter is equipped with a stand on wheels that allows the plotter to be moved depending on the needs, and a practical foil basket reducing the undesirable effect of electrifying the foil, which during cutting can “collect rubbish” from the floor, which often causes the knife to blunt quickly and the mechanics of the device become contaminated . Jaguars are very fast and quiet. The wide range of pressure adjustment on the knife allows cutting practically all types of foil offered on our market. Only Jaguar plotters have the function of an extended working area – cutting without side margins. Another novelty is the introduction of the active knife simulation function, which improves the precision of cutting in very thick materials. Compared to the competition, the increased number of pressure rollers and a precisely constructed foil feeder allow for cutting even very long sections without supervision of the device. Easy-to-use control panel with LCD screen, with messages in English makes working with Jaguar easy and efficient.

Advantages of Jaguar V plotters:

- A simple control panel that is easy to use for a professional as well as a novice user, allows you to set all the parameters of the plotter. The display can show information in one of eight languages.

- The included control software allows you to install the plotter in Windows 95/98/2000 / XP / 7/8/10 as a printer. Thanks to this, the user can cut graphics directly from graphic vector programs such as CorelDraw !.

- The sensors of the beginning and end of the material enable automatic measurement of the length of the film, stop the plotter when the material runs out. They save time, money and protect the plotter from damage.

- Variety of accessories. Accessories available for GCC plotters make them applicable in various activities. Using various types of knives, we can cut all kinds of films on the base and, using a special protective tape, cut through the cardboard. By replacing the knife with a felt-tip pen, we can draw detailed technical drawings. We can use an optional hole punch to create templates from various materials.

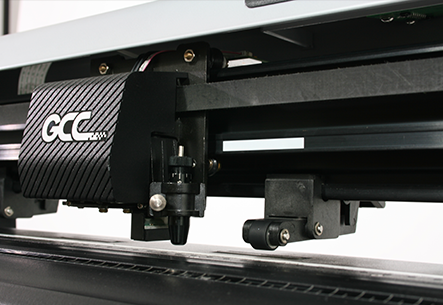

- Pressure rollers. Jaguar V plotters with a working width of 61 and 76 cm have 3 pressure rollers, while models with a working width of 101 and 132 cm have 4 pressure rollers, which allows for guaranteed repeatability of cutting up to 10 meters. All rollers are lowered and raised simultaneously by the control lever. Once all the rollers have been lowered, it is possible to correct the position of any roll by lifting it with a small lever on the back of each roll and sliding it into place.

The freely adjustable knife pressure from 0 to 600 grams allows you to easily cut various materials, from delicate vinyl foils through fluorescent and metallized foils to thick and hard masking foils for sandblasting in stone. Thanks to such parameters, Jaguar V plotters are used not only in advertising but also in stonework and glass factories.

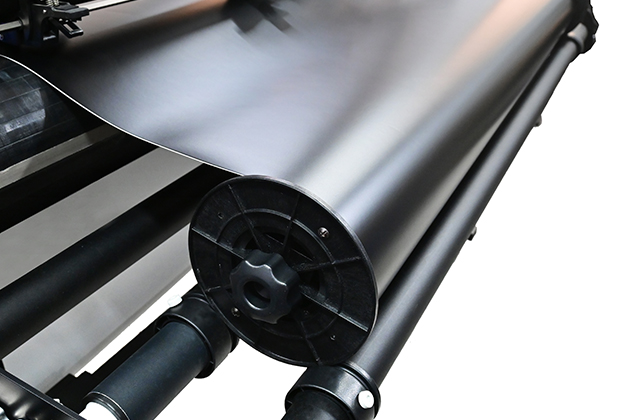

- A functional and easy-to-use media feeding system (consisting of two guide rollers, securing rings and a feeder) allows you to cut very long graphics without the constant supervision of the operator. Guaranteed repeatability is 10 meters of cutting length.

- The trimming function significantly increases the cutting performance, especially in thick materials. Enabling this function extends the first and last vector of each object by a given value.

- The plotter can be equipped with a pen, so that each user can make project drawings and templates on any material.

- Electronically set knife offset. Knife offset adjustable with an accuracy of 0.025 mm – this parameter specifies the distance of the knife tip from the center of rotation of the knife – the lack of its precise adjustment or inaccurate setting results in poor cutting of small elements and straight (acute) angles.

- Active knife simulation function. Enabling the function causes the plotter to cut all vectors in a specific order in order to minimize the number of knife revolutions during cutting. The plotter divides the graphic into groups of vectors lying on the same plane at the same angle, then cuts the extracted parts one by one. The use of this function significantly improves the quality and precision of cutting in thick masking and metallized films.

- Reliable and precise motors. Thanks to the use of reliable DC servo motors with a built-in precision positioner, the maximum cutting speed of up to 1530 mm per second was achieved without loss of quality!

- Cutting optimization function. When the plotter moves the knife over the material, its movements will be optimized, the plotter will cut by sorting individual parts of the graphics so that there are as few empty runs as possible.

Additional technical advantages and TECHNICAL SPECIFICATIONS

- The Jaguar V series features a standard Automatic-Aligning System (AAS II) to guarantee precise contour cutting by automatically detecting the registration marks on digitally produced images.

Functions include:

1st-mark auto-detection

4-point positioning

Segmental positioning

Multiple copies

- Jaguar V series supports triple port connectivity with USB, serial and Ethernet ports. The USB port provides faster and convenient data transmission between the computer and Jaguar V. Ethernet connection enables multiple Jaguar V to be operated by one PC and multiple PCs to share a single unit. Triple port connectivity provides sign makers a great flexibility for data transmission.

- At up to 60 inches per second of cutting speed, Jaguar V series cutting throughput simply outperforms the competition.

- The exclusive grid drum and precisely engineered mechanism to provide superb tracking ability.

- The tangential mode performs clean cuttings, diminutive letterings and intricate graphics which yield smooth corners and sleek edges on thick materials.

- The media support system is fully adjustable. It supports media on standard cores and resolves media drifting and alignment problems to ensure better tracking.

The easy-to-use and multi-language control panel can remarkably simplify complex tasks. It provides various functional settings to meet users’ needs.

The easy-to-use and multi-language control panel can remarkably simplify complex tasks. It provides various functional settings to meet users’ needs.

- Each pinch roller can be operated respectively to selective position wherever is proper to optimize its utility.

Technical data:

- Max. cutting width: 610 mm ( 24 ” )

- Max. media width: 770 mm ( 30.3 ” )

- Number of pinch lorrels: 3

- Acceptable Material Thickness: 0.8 mm

- Max. Cutting Speed: 1530 mm/sec (60 ips) (at 45° direction)

- Max. Cutting Force: 600 g

- Distance Accuracy: ?0.254 mm or ?0.1% of move, whichever is greater

- Memory Buffer: 32 MB /16 MB (when using AAS)

- Power Supply: 100~240 VAC 50 / 60 Hz (auto switching)

- Dimension (H x W x D) mm: 412 x 950 x 486